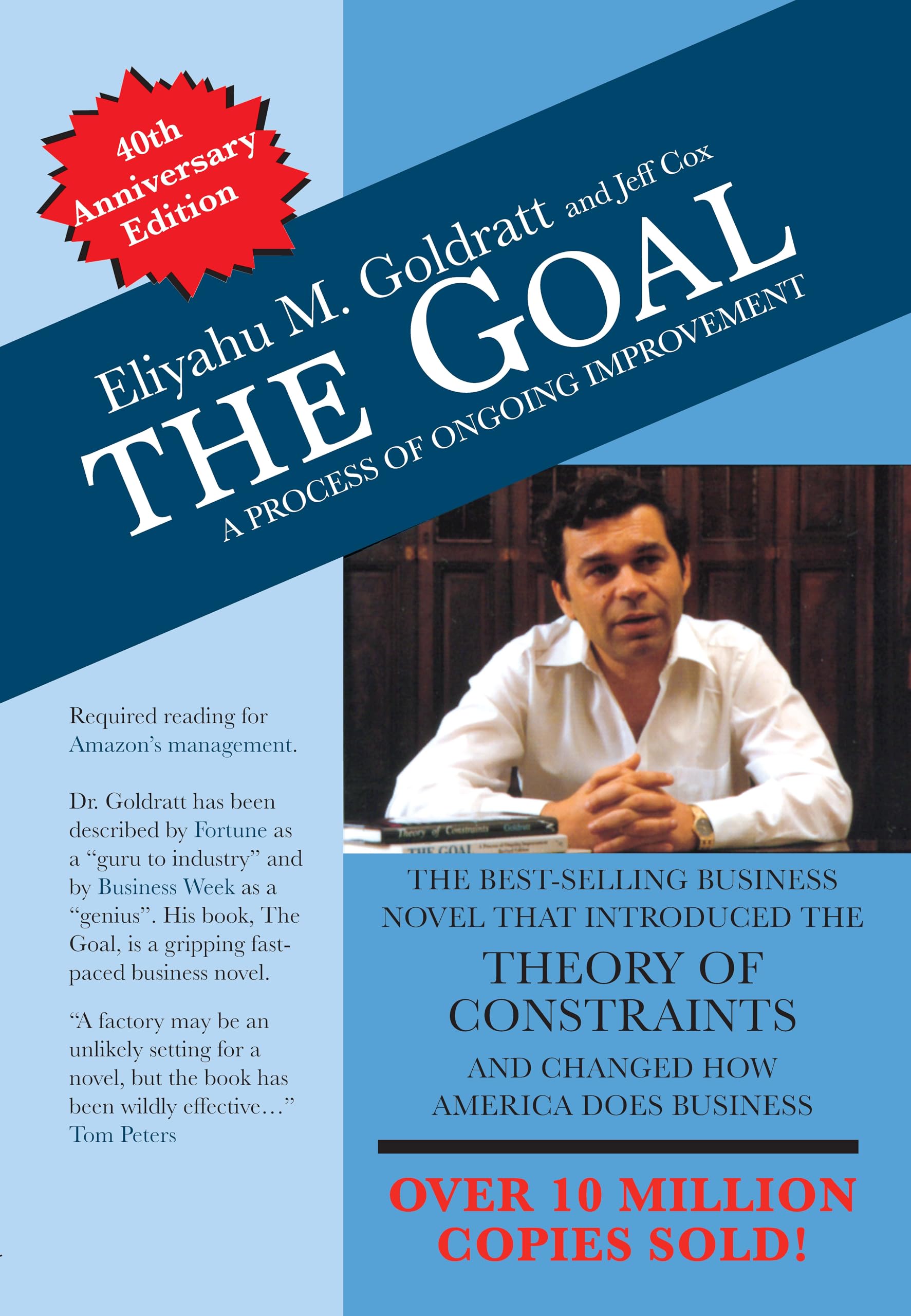

The Goal: A Thought Process Outline

The Goal by Eliyahu M. Goldratt and Jeff Cox presents a thought process for improving a manufacturing organization. This outline summarizes the key steps and concepts:

1. Identify the Goal:

- The fundamental goal of any manufacturing organization is to make money.

- All other activities are simply means to achieve this goal.

2. Develop Relevant Measurements:

- Traditional measurements like net profit, ROI, and cash flow are important for overall financial health, but they are not effective for managing daily operations.

- Introduce new measurements that directly relate to the goal of making money and are applicable at the operational level:

- Throughput: The rate at which the system generates money through sales.

- Inventory: All the money that the system has invested in purchasing things which it intends to sell.

- Operational Expense: All the money the system spends in order to turn inventory into throughput.

3. Identify the Constraint:

- Every system has a constraint (bottleneck) that limits its ability to achieve the goal.

- The constraint can be physical (a machine, a process) or policy-based (a rule, a measurement).

- Identifying the constraint is the first step in improving the system.

4. Exploit the Constraint:

- Once the constraint is identified, focus on making the most of it.

- This means ensuring that the constraint is never idle and is always working on the most important tasks.

- Subordinate all other processes to the needs of the constraint.

5. Elevate the Constraint:

- If the constraint is still limiting the system's performance, invest in improving its capacity.

- This might involve purchasing new equipment, adding staff, or changing policies.

6. Repeat the Process:

- Once a constraint is elevated, another constraint will emerge.

- The process of identifying, exploiting, and elevating constraints is an ongoing cycle of improvement.

7. Challenge Assumptions and Common Practices:

- Many ingrained practices and assumptions can hinder improvement.

- Question the validity of existing policies and procedures.

- Be open to new ways of thinking and operating.

8. Think in Terms of Cause and Effect:

- Analyze problems by tracing their root causes.

- Use a logical "If...Then" approach to understand the connections between actions and results.

9. Develop Thinking Processes:

- The Goal emphasizes the importance of developing effective thinking processes for managing complex systems.

- These processes should enable managers to identify core problems, find solutions, and implement changes.

10. Embrace Continuous Improvement:

- The Goal advocates for a culture of continuous improvement.

- This means constantly seeking ways to enhance throughput, reduce inventory, and decrease operational expenses.

- Everyone in the organization should be engaged in the improvement process.

Listen to the Podcast